PRODUCTS

Are any of the following items bothering you?

To produce food for retort pouches, two people must place

a 50 kg kiln into a cooking pot that weighs over one ton and

repeatedly fill it with ingredients. Is there a way to make this task easier?

Many food companies use our balancers, which are perfect for work

that involves carrying heavy items repeatedly that cannot be fully

automated when producing small lots of a wide variety of products.

Control is also possible for small actions like tilting the tank and putting

in just a small amount of ingredients. Hence, please feel free to consult

with us about your needs.

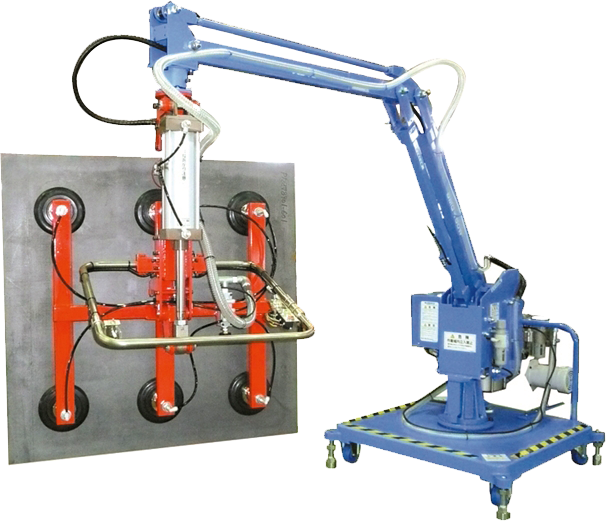

We manufacture glass that is used for displays on products like smartphones.

Before we send the glass to the manufacturer of the product that is going to use it,

the glass is several meters squared in size. Is there a way we can easily convey such large glass?

Reducing the work involved in conveying glass is what the balancer

is really good at. It can easily and safely carry large and heavy glass sheets

to processing machines. It has an attachment to sucker the glass plate as well

as an inversion mechanism. Please take advantage of it if you are considering

reducing labor and improving the work environment.

We are a materials company that manufacturers exterior facing

materials for houses and we verify large, three meter facing sheets

that are L-shaped, classifying them as a pass or fail. We used to use

several people to carry them, but we have a shortage of staff

and can no longer do it by hand.

Our balancers can also be used to efficiently perform work like this

that requires several people to accomplish. An attachment or

mechanism to vacuum and level complicated shapes and construction

boards can also be built-in. We will check out your operations on-site

to propose device specifications and how to install devices, so please

do not hesitate to contact us.